Testing Item:Sublimation Test Instruction

Test Principle: Test color migration condition and degree of fabric

Test Step1: Use AATC Test Fabric Wrap Test Materials and Stitch Together

Attention Point:

- The white test fabric should be AATC (without any fluorescent competent)

- The test fabric size is 60mm*60mm

- The test fabric is separate fromnylon fabric(right, code: N) and polyester fabric(left, code: P), request use separate boxes to put and mark to distinguish them.

- D.The test fabric should be stitched together by handand use pencils to mark the

AATC Test Fabric

The test fabric stitched together by hand and use pencils to mark code

Test step2:Put the Test Materials Under 21pieces of Sheet Steel(Thickness:1mm),Bear Load 10LBS

Attention Point:

- Put the test materials between sheet steel, one test piece can be placed in per sheet steel.

- Bear load 10LBS(weight8LBS,sheet steel 2LBS)

- Press mold and system of perspiration are natural vertical placement, do not apply pressure to increase

- Tighten the screws on both sides after placing

- Set machine to 120℃ preheat for one hour

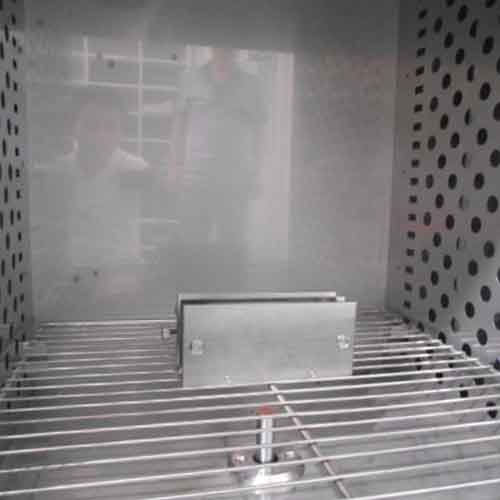

- Put the test pack in the middle of the machine after taking off the weight.Set the data of machine to:80℃ -80min(first time )or 80℃ -48H(when first time test is failed)

- Close the machine door and process testing

Test Step3:Finished the Testing and Take Out the Test Panel

Attention Point:

- The machine stops when the time is up

- Put on the cow leather glove and take out the testing panel

- Take out the stitching on the testing panel which is split into testing materials and a white panel. Hang with a clamp until getting cool.

Test Step4:Judgement Testing Result

Attention Point:

Put cooling testing materials together with a pollution color swatch Judge the degree

of pollution under the multifunctional light color matching box.

If the pollution level is up from LV.4(including LV.4), the result is OK.

(Should use a 45°degree angle to observe it.)